Cowl panel replacement requires specialized tools, safety gear, and high-quality materials for a factory-like finish. Efficient workflow management involves gathering tools, preparing the workspace, removing old panels, inspecting surfaces, installing new ones, and maintaining cleanliness to avoid errors and hidden damage. For accurate, time-efficient results, auto body shops should follow these steps and consider professional guidance.

Cowl panel replacement is a crucial task for maintaining vehicle performance and aesthetics. This comprehensive guide delves into the essential aspects, providing tips for efficient workflow management. From understanding the process to gathering the right tools and materials, we outline a step-by-step approach to ensure success. Learn best practices to streamline the job, avoid common pitfalls, and enhance your overall experience with expert advice tailored for cowl panel replacement.

- Understanding Cowl Panel Replacement: Essential Tools and Materials

- Step-by-Step Guide: Efficient Workflow Techniques for Successful Cowl Panel Replacement

- Best Practices for Streamlining the Process and Preventing Common Pitfalls

Understanding Cowl Panel Replacement: Essential Tools and Materials

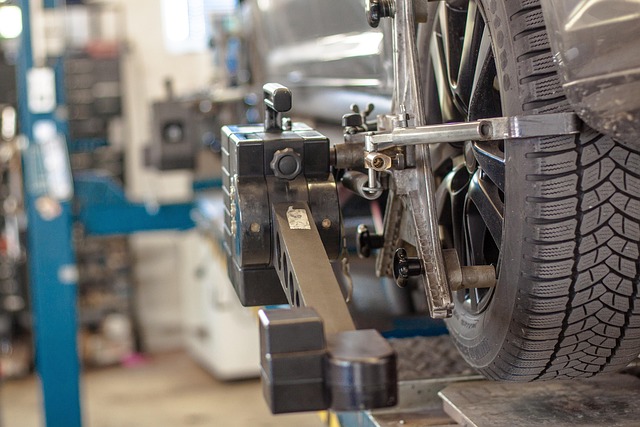

Cowl panel replacement is a critical aspect of collision repair, requiring precision and the right tools for an efficient workflow. Before beginning the process, it’s essential to gather all necessary materials, ensuring you have everything needed for a seamless repair. Standard tools include specialized torches, clamps, and grinders designed for metalworking. Additionally, high-quality replacement panels, matching paint, and primers are crucial for achieving a factory finish.

For a successful cowl panel replacement project, consider investing in top-tier auto glass repair equipment and materials. This includes safety gear like gloves and protective eyewear. Proper preparation involves cleaning the damaged area thoroughly to ensure adhesion of new parts. It’s also vital to mask surrounding areas to prevent paint transfer during the repair process, ensuring minimal disruption to other car collision repair tasks.

Step-by-Step Guide: Efficient Workflow Techniques for Successful Cowl Panel Replacement

Efficient workflow management is key when conducting a cowl panel replacement, ensuring the process is seamless and reduces potential errors. Here’s a step-by-step guide to help streamline this auto collision repair task:

1. Preparation: Begin by gathering all necessary tools and parts. This includes the new cowl panel, fasteners, and any required primers or paints. Ensure your workspace is clean and organized for a smooth car body restoration process.

2. Safety First: Put on protective gear, including gloves, eye protection, and an apron to avoid contamination from debris. This safety measure is crucial, especially when handling auto collision repair components.

3. Remove the Old Panel: Carefully disassemble any surrounding parts to gain access to the cowl panel. Use a suitable jack or lift point to safely raise and remove the damaged panel. Take note of how it was attached for future reference during the car body restoration process.

4. Inspect and Clean: Examine the new panel and the area where it will be installed. Ensure both surfaces are clean, free from debris, and prepared for bonding or painting. This step is vital to guarantee a proper fit and long-lasting results in your body shop services.

5. Install the New Panel: Position the new cowl panel carefully, ensuring it aligns with the vehicle’s structure. Secure it in place using appropriate fasteners, following the manufacturer’s guidelines.

6. Final Touches: Once the panel is firmly attached, double-check all connections and tighten any loose parts. Clean up any excess material or debris left from the installation process to maintain a professional finish.

Best Practices for Streamlining the Process and Preventing Common Pitfalls

When undertaking cowl panel replacement, best practices involve preparation and attention to detail. Begin by gathering all necessary tools and parts in advance, ensuring a well-organized workspace for a smoother process. Next, carefully remove the damaged or old cowl panel, taking note of its installation method and any specific requirements. This step is crucial as it prevents missteps during reassembly.

To avoid common pitfalls, double-check fitment before proceeding with replacement. Ensure all components are correctly aligned and secured to prevent future issues. Regularly cleaning the area during work can also help detect hidden damage or debris that could affect the final result. Moreover, seeking guidance from experienced personnel in a collision repair shop or body shop services can significantly enhance the efficiency of your workflow, ensuring the cowl panel replacement is done accurately and within the desired timeframe.

Cowl panel replacement doesn’t have to be a daunting task. By understanding the essential tools and materials required, following a well-structured step-by-step guide, and adopting best practices, you can efficiently manage your workflow and ensure a successful outcome. Remember, proper techniques and organization are key to avoiding common pitfalls and making the process smoother for both beginners and seasoned professionals.